| 26 |

|

Online monitored Fermentor with a lab-scale facility with a capacity of 14 L is also available at CIAB for the same application as mentioned above. (Make: New Brunswick Inc.). Monitoring probes: pH and Temperature. |

| 27 |

|

Membrane Filtration is one of the physical separation processes in which fluid passes through a specific type of membrane, letting water to penetrate and to separate the suspended solid components. According to the size of the molecules present in the mixture, the suitable membrane (micro, ultra, nano and reverse osmosis) can be chosen to concentrate it. Membrane Filtration System (pilot-scale) available at CIAB consists of all three membranes, viz., micro, nano and ultra, which can be operated one after another to separate the solid components dissolved in water accordingly. The type of membrane employed is a spiral-bound membrane. The available membrane range for filtration as follows: a) Microfiltration: 0.2 to 0.4 micron, b) Ultrafiltration: 1000D-10KD, c)Nanofiltration: 100D-1000D and d) Reverse osmosis: >100 D. Minimum amount of sample required is 40 L. Fermentation broth, whey protein, sugar components, etc., can be filtered using this system. This system has a wide application in the food and beverage industry. |

| 28 |

|

Membrane Filtration System (lab scale) is also available at CIAB in which one filtration can be performed at a time with a specific membrane. This lab-scale membrane filtration system offers to use all four layers (micro, ultra, nano and reverse osmosis) and is flexible in terms of changing one membrane to the other. The type of membrane employed is a spiral-bound membrane. The available membrane range for filtration as follows: a) Microfiltration: 0.2 to 0.4 micron, b) Ultrafiltration: 1000D-10KD, c)Nanofiltration: 100D-1000D and d) Reverse osmosis: >100 D. Minimum amount of sample required is 5 L. Fermentation broth, whey protein, sugar mixtures, etc., can be filtered using this system. This system has a wide application in the food and beverage industry. |

| 29 |

|

A twin-screw Extruder is a machine designed to perform extrusion process through which a desired shape of the product can be obtained. The extruder (twin-screw extruder) available at CIAB can thermomechanically transform raw materials to the desired shape in a relatively short time at high temperature under pressure conditions. The major application of this machine in food processing is to cook biopolymer-based raw materials to produce textured food and feed products, such as ready-to-eat breakfast cereals, snacks (savoury and sweet), pet foods and feed pellets. The major advantage of intermeshing co-rotating twin-screw extruders is remarkable mixing capability which confers exceptional characteristics to extruded products and adds significant value to the processing unit. To make use of this twin-screw extruder, the raw materials can be in the form of solid powders, granulates, flours. |

| 30 |

|

Spray Dryer is an instrument used to obtain a dry powder from a liquid or slurry sample. A Spray Dryer Unit is a well-known one-pot continuous process in which a stream of liquid is separated into solute as a solid and liquid solvent as a vapour. The liquid or slurry sample is sprayed through a nozzle to form droplets and exposed to the flow of hot air to remove moisture quickly to get dry powder particle. Spray Dryer (Semi-pilot scale) available at CIAB can function at a rate of 5 ml/min (depends on the nature of the sample) at a temperature range of 100 - 180 C (inlet) and 50 -160 C (outlet). Temperature and air pressure can be maintained according to the nature of the sample. Spray Dryer (Semi-pilot scale) is generally used in food industries (e.g., milk, whey protein, fruits and vegetable extracts, egg and soya protein), beverages (e.g., tea and coffee), Fruit and Vegetables (e.g., tomatoes and coconut milk) for obtaining dry powder particles. |

| 31 |

|

Kjeldahl Nitrogen Analyzer is typically used to measure the percentage of protein content in a sample. The method followed in this measurement is based on catalyst assisted (K2SO4 and CuSO4) strong acid (H2SO4) digestion, distillation using NaOH and titration using HCl and boric acid which captures the nitrogen present in the sample. The percent nitrogen can then be converted into percent protein via the conversion factor, which may vary from sample to sample. Nitrogen Analyser is used to study the protein content in food samples. |

| 32 |

|

Protein Purification System is used to purify or desalt the crude protein extracts or isolate one protein from a mixture of complex proteins. The principle is based on ion-exchange chromatography, affinity chromatography, gel filtration /buffer exchange and hydrophobic interaction chromatography (HIC gradient elution). Protein Purification System (AKTA Prime) can be used to purify or desalt the given protein sample. |

| 33 |

|

Rheometer is a device that measures the changes in viscosity and viscoelasticity of a liquid, suspension or a slurry in response to applied forces i.e. shear stress and shear strain. Unlike viscometer this instrument measures the rheology of the fluid. A rheometer extends the measurement range from 10-6 to 10-5 s-1. Rheometer (TA Instruments) can measure the viscosity variables of non -Newtonian fluids, and to study the rheology of polymers and food materials such as sauces, ketchup. |

| 34 |

|

Ultracentrifuge Floor Model unit is an instrument to separate the materials (solid particles) contained in the sample through the process of centrifugation. The separation takes place based on the density of the fluid or liquid or the material to be separated. Relative Centrifugal force (RCF) is responsible for the separation of the contents in aqueous solution. The capacity of this Centrifuge Floor Model (LYNX 6000 Centrifuge) is six litres, i.e. at a time six-litre sample can be centrifuged. The machine operates at different RPM’s (revolutions per minute), time and temperature. We can set all these parameters based on the requirement of the samples that need to be centrifuged. Centrifuge dimensions & volumes: 36.6 × 27.6 × 31.7 in. (93.0 ×70.0×80.5 cm), 6×1000 ml; Speed range: 29,000 RPM or 100,605 × g rcf Temperature Range: -20º to +40º C |

| 35 |

|

Lyophilizer (Freeze-dryer) is a dehydration technique used mainly for drying of samples. The principle is based on the sublimation where the solid-state is directly converted to the gaseous state without passing through the intermediate liquid state. The previously frozen sample can be vacuum dried in a freeze dryer. Lyophiliser (CHIRST; DELTA 2-24 LSC) can be used for preservation of products (e.g., enzymes, proteins, nanomaterial’s, polyphenolic compounds, food products), to improve the shelf life of various products, and for packaging of reconstituted liquid products which are frozen and solidified through freeze-drying. Note: Only organic solvent-free samples will be accepted for drying. |

| 36 |

|

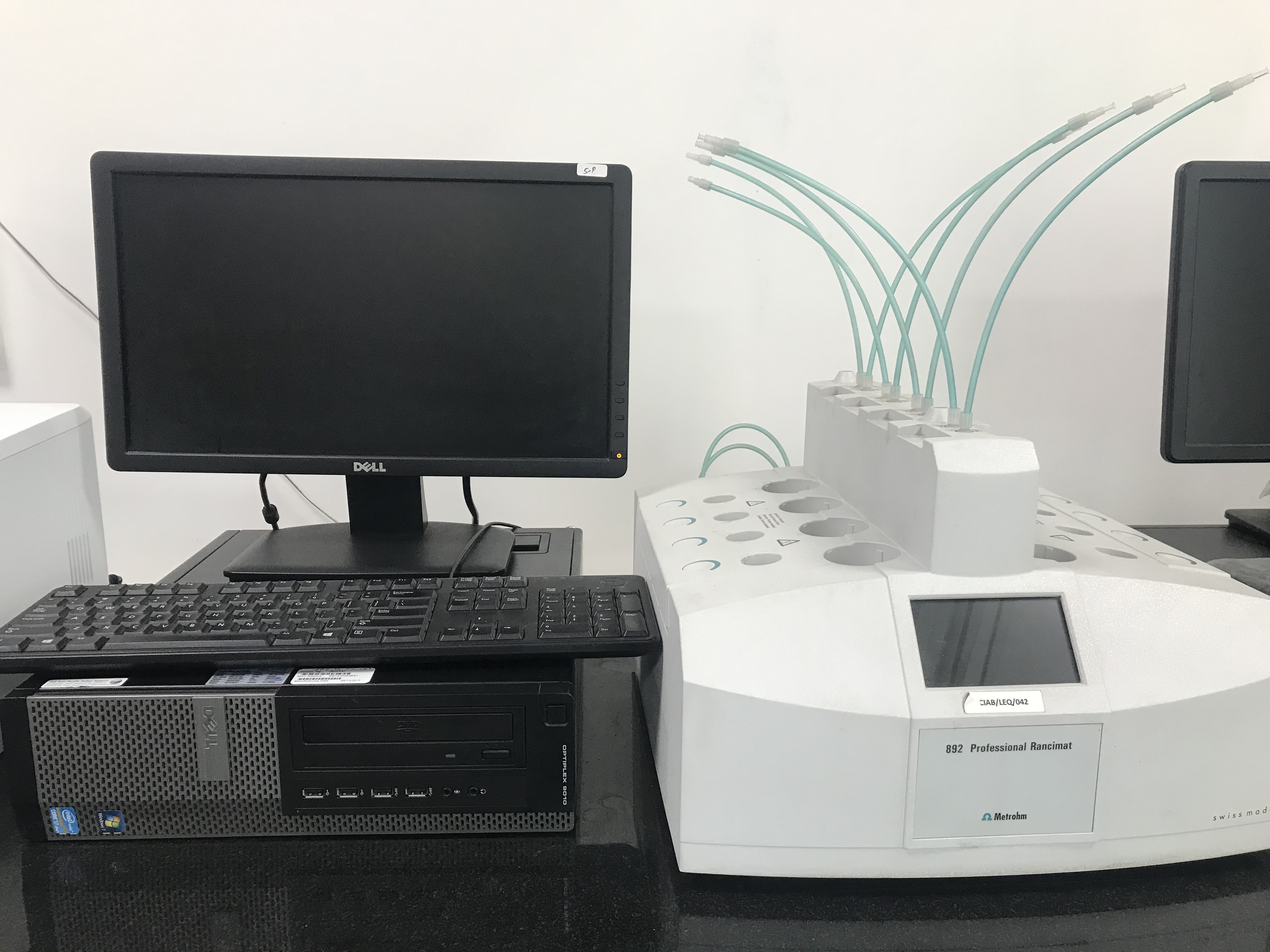

Rancidity analyzer is mainly used for measuring the oxidative rancidity of oil samples. Rancid oils produce peroxides which get dissolved in water. Peroxides can be detected in terms of induction time or oil stability index (OSI) μS (Siemens)/cm in this equipment. Rancimat (Metrohm 892) can be used to analyse the oxidation stability (shelf life), the antioxidant activity of fats and oil samples. Rancimat can also be used to measure the oxidation stability of oil- and fat-containing foods such as instant noodles, cookies, and nuts, as well as cosmetics if they contain fats or oils. |

| 37 |

|

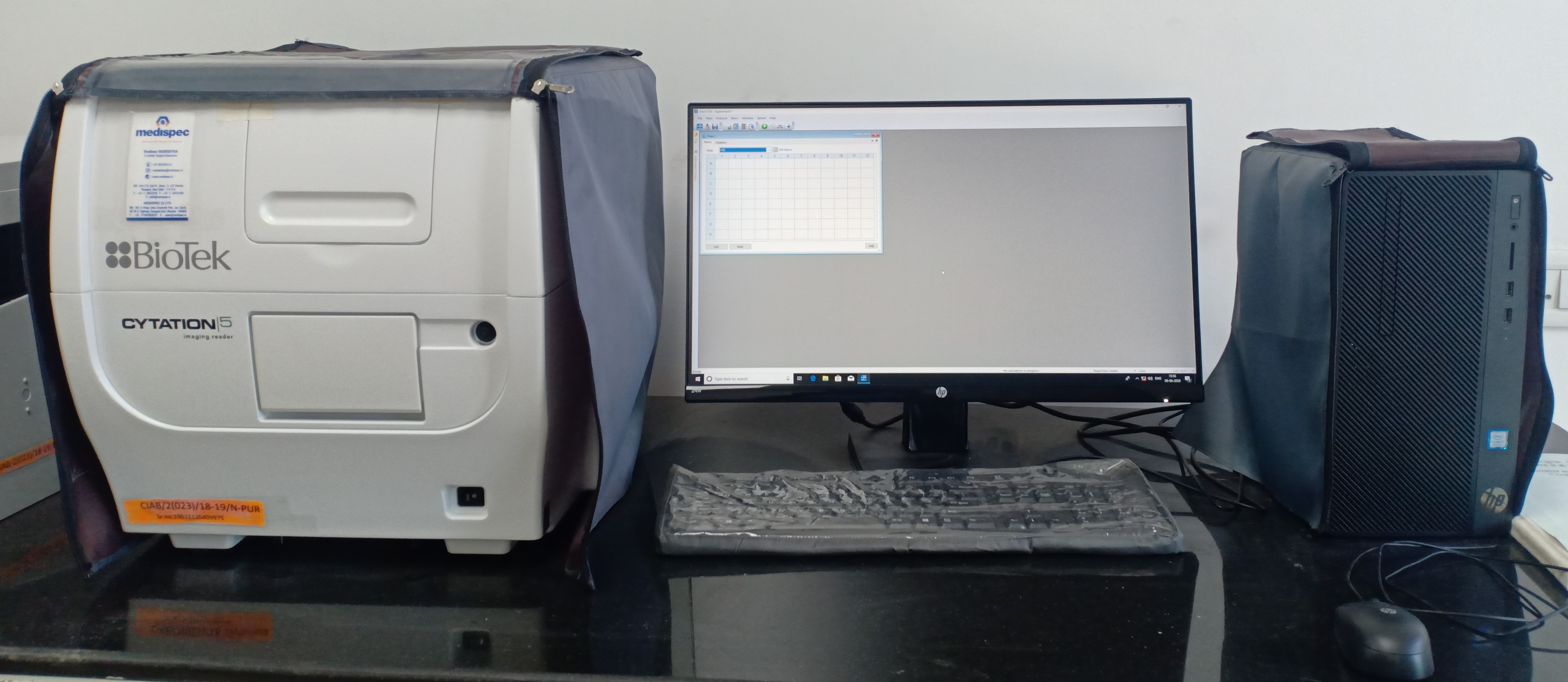

Multimode Microplate Reader Spectrophotometer detects light signals produced by a sample, converted by a sample or transmitted through a sample. Multimode Microplate Reader Spectrophotometer (Bioteck; CYTATION 5) can detect in five different modes such as UV-Vis absorbance, Fluorescence intensity, Luminescence, Fluorescence polarization, Time-resolved fluorescence and Alpha and has various microplate types (Monochromator: 6- to 384-well plates; Filters: 6- to 1536-well plates and Imaging: 6- to 1536-well plates). This instrument has application in various areas such as cell-based assays, biomarker assays, imaging applications, protein quantification, kinetic assays and micro-volume nucleic acid and protein quantification. Wavelength range: 230 - 999 nm, 1 nm increments Monochromator bandwidth: 4 nm (230 - 285 nm), 8 nm (>285 nm) Reading speed (kinetic): 96 wells: 11 seconds; 384 wells: 22 seconds |